Invest in Your Workflows: Unlock Possible with Stacking Conveyors for Sale

Invest in Your Workflows: Unlock Possible with Stacking Conveyors for Sale

Blog Article

Unleash the Power of Piling Conveyors for Optimal Reusing Efficiency

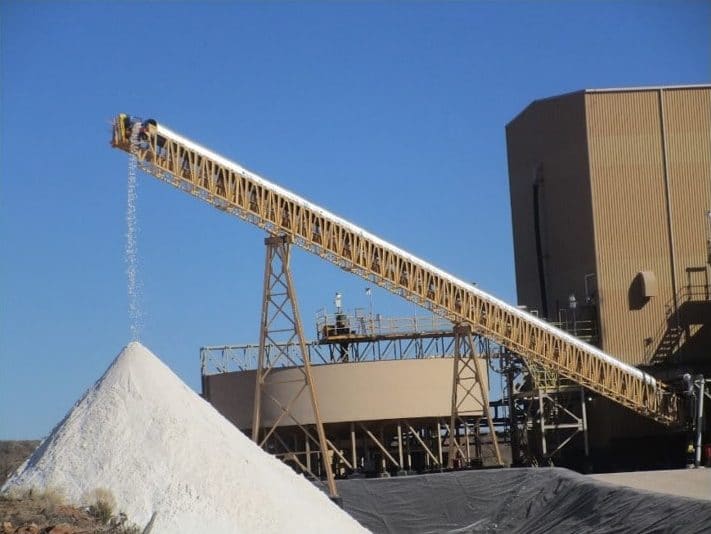

And that's where stacking conveyors come into play. These unassuming machines hold immense capacity, qualified of transforming the reusing efficiency - stacking conveyors for sale. With their capacity to increase arranging effectiveness, improve product handling, streamline the reusing procedure, and enhance area usage, piling conveyors offer a cost-effective remedy that can truly let loose the power of recycling.

Increased Arranging Efficiency

One of the key benefits of stacking conveyors is their capacity to handle huge volumes of materials. By automating the arranging process, these conveyors can handle a higher throughput of recyclables, reducing the requirement for hands-on labor and boosting overall performance. This not only conserves time yet additionally decreases the danger of human mistake, ensuring a more accurate arranging procedure.

Moreover, stacking conveyors permit the segregation of various sorts of recyclables into different heaps or bins. This makes it easier for reusing facilities to procedure and sell these products to producers who can transform them into brand-new items. By improving the arranging effectiveness, piling conveyors assist make best use of the value of recyclables, adding to a more successful and sustainable recycling market.

Boosted Product Handling

Stacking conveyors play an essential function in enhancing product dealing with performance within reusing centers. These specialized conveyor systems are created to efficiently move and stack different kinds of recyclable materials, such as paper, plastics, steels, and glass. By automating the procedure of moving materials from one place to one more, stacking conveyors not only save time but likewise boost employee safety and performance.

Among the key benefits of using piling conveyors for product handling is their capacity to take care of big volumes of recyclable products. These conveyors are developed with adjustable elevations and angles, enabling them to get to greater levels and stack products in an organized fashion. This not just makes the most of storage space capability yet additionally makes it easier for employees to accessibility and get materials when needed.

In addition, piling conveyors are furnished with sophisticated functions such as variable speed controls and automated arranging systems - stacking conveyors for sale. This enables them to sort and separate various kinds of recyclables as they are delivered along the conveyor belt. By improving the arranging process, these conveyors assist to boost reusing performance and reduce the risk of contamination

In addition, stacking conveyors are designed to withstand rough environmental conditions generally found in recycling centers. They are developed with durable products and equipped with dirt reductions systems to ensure trustworthy and constant procedure. This minimizes downtime and upkeep expenses, even more enhancing the overall material dealing with efficiency within the facility.

Streamlined Recycling Refine

The application of reliable stacking conveyors in reusing facilities causes a structured recycling procedure. These conveyors play a crucial role in optimizing the overall performance and find this productivity of the reusing operations. By automating the movement of materials, they remove the requirement for hands-on sorting and handling, lowering the risk of injuries and enhancing employee safety and security.

Piling conveyors permit for the seamless transfer of recyclable materials from one processing phase to an additional, making certain a continual and smooth circulation throughout the reusing procedure. They can handle a wide variety of materials, including paper, metal, plastic, and glass, with differing sizes and weights. This convenience enables reusing centers to efficiently refine different kinds of waste streams, increasing their capacity to handle larger volumes of recyclable products.

In addition, stacking conveyors facilitate the segregation of various products, making certain that each recyclable component is guided to its respective handling line. This splitting up not just boosts the reusing performance however additionally enhances the top quality of completion items. By reducing contamination and protecting the integrity of the products, stacking conveyors add to the production more information of high-grade recycled products that meet the marketplace need.

Additionally, using piling conveyors minimizes the requirement for hand-operated labor, enabling reusing facilities to reapportion their workforce to even more value-added jobs. This optimization of personnels leads to expense financial savings and increased functional performance.

Improved Room Application

With the execution of effective stacking conveyors, recycling facilities can enhance their area use for enhanced operational effectiveness. Stacking conveyors are created to make best use of storage space capability by up and down piling materials in a compact and orderly way. This permits recycling centers to take advantage of their offered area, decreasing the demand for extra storage areas and lessening mess on the plant flooring.

By utilizing stacking conveyors, reusing centers can develop a more reliable and streamlined operations. The ability to pile materials vertically removes the need for wide aisles and big open spaces, freeing up valuable flooring room for various other operations or equipment. This improved room application not only boosts the general performance of the center yet additionally improves employee security by decreasing the threat of injuries and mishaps triggered by jampacked workspace.

Additionally, stacking conveyors allow reusing centers to keep and process a bigger volume of materials within a smaller impact. This is especially valuable for facilities with restricted area or those seeking to increase their procedures without sustaining considerable costs for added land or structures. By taking full advantage of space application, reusing centers can enhance their handling click for more info capacity, satisfy expanding need, and potentially create higher profits.

Cost-effective Reusing Solution

Executing an economical recycling option is necessary for enhancing operational efficiency and making best use of productivity in recycling facilities. As the demand for recycling continues to grow, it is essential for facilities to find ways to reduce expenses while maintaining premium outcome. Piling conveyors provide a cost-effective service by streamlining the recycling procedure and minimizing manual work.

Among the key advantages of stacking conveyors is their capacity to effectively move products over cross countries. By getting rid of the need for multiple conveyors or hand-operated handling, stacking conveyors minimize the general cost of transportation. Additionally, these conveyors are designed with adjustable height and disposition, permitting simple customization to fit the specific requirements of the center.

Furthermore, stacking conveyors boost the sorting and splitting up procedure, which is essential for reusing centers. stacking conveyors for sale. These conveyors can be geared up with functions such as magnetic separators, eddy existing separators, and choosing stations, allowing reliable product partition. This not just improves the quality of recycled materials however also decreases the quantity of waste that ends up in landfills

Final Thought

To conclude, making use of stacking conveyors can substantially improve reusing performance by increasing sorting performance, boosting material handling, simplifying the reusing process, and maximizing room usage. This cost-effective remedy uses numerous advantages for reusing centers, promoting a more sustainable and reliable strategy to lose monitoring.

To boost reusing productivity and streamline operations, the execution of piling conveyors has actually verified to considerably improve the arranging performance in reusing facilities.Piling conveyors play a critical function in improving material taking care of effectiveness within reusing facilities. Piling conveyors are designed to maximize storage capability by up and down piling products in a small and well organized fashion.Furthermore, piling conveyors allow reusing facilities to keep and process a larger quantity of products within a smaller impact. By getting rid of the requirement for several conveyors or manual handling, stacking conveyors reduce the overall expense of transportation.

Report this page